-

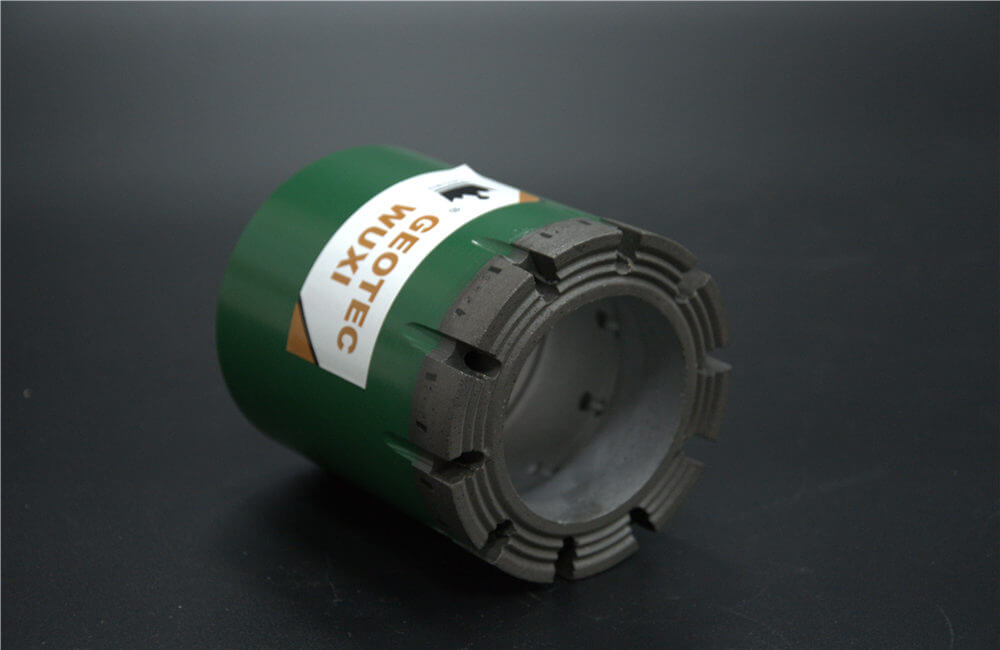

Standard V ring type:

Standard V ring type:

• Can be used on most impregnated core bits

• Great fluid circulation from the inside to the outside

• Available with wider or larger waterways -

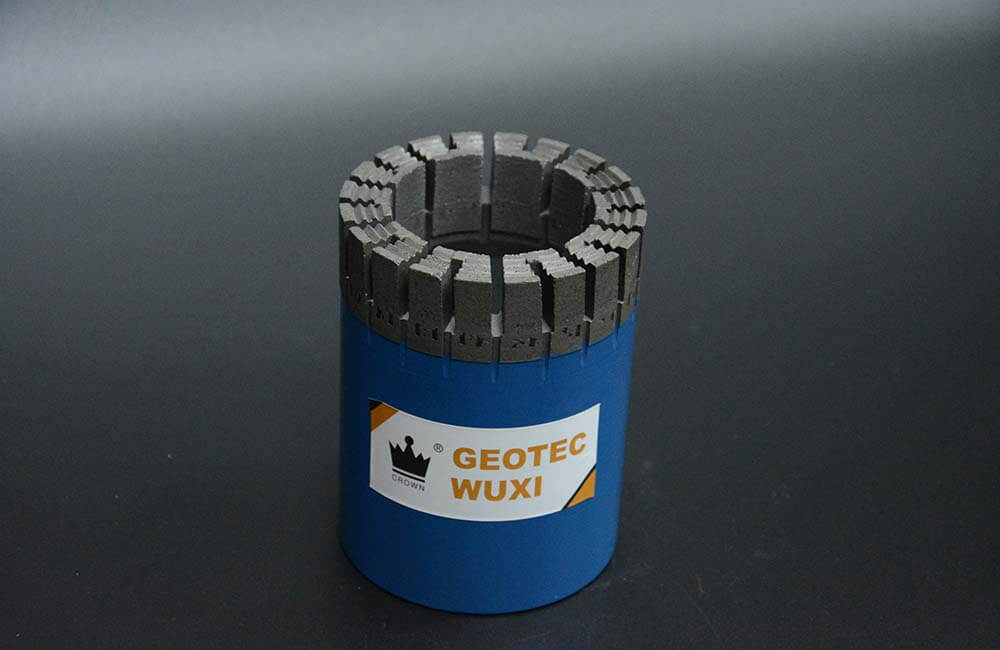

Turbo type:

Turbo type:

• Greater ejection of fluids and cuttings

• Reduced contact area with the same flushing performance

• Recommended for higher rotation speeds

• Available with wider or larger waterways -

Face Discharged type:

Face Discharged type:

•Recommended for very soft and broken ground

•The face discharge ports offer excellent flushing to prevent blockages in the waterway channels

•Available with wider or larger waterways -

Vortex type:

Vortex type:

•Recommended for very hard, abrasive and broken ground -

Non-core Type:

Non-core Type:

•Work together with down hole motor, such as directional drilling

•Downhole accident may be appropriate as well

Impregnated Diamond Bit

Impregnated diamond bit,the most commonly useful bit in the mineral exploration,as they have the widest range of application.

Features of Impregnated diamond bit

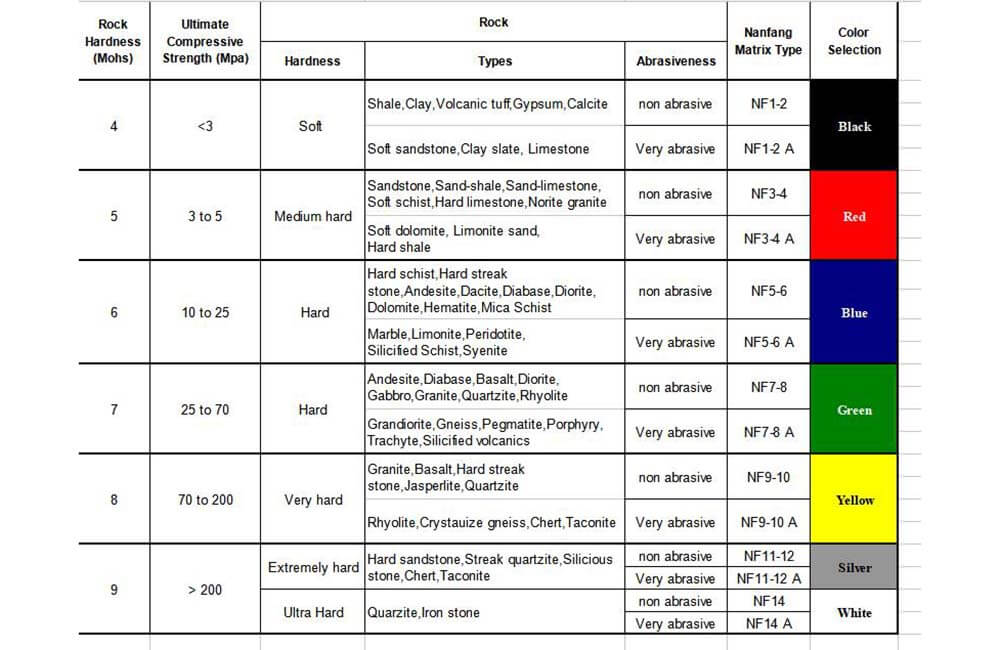

1. Carefully selected grades of high quality synthetic diamond which distributed in the depth of bit's matrix series

2. The matrix layer of the crown contians a uniform distribution of these crystal that are embedded in powdered metal bond.

3. Designed to expose new diamonds to the bits' cutting face as wear occurs.

4. Fast penetration rate is maintained as a result of this action.

5. Optimum diamond size, concentration and matrix type are dependent on the hardness and abrasiveness of rock formation.

6. Impregnateion Depth: 4/7/9/10/12/13/16/24mm or based on consumers' need

Size Available

|

Drill Bit Available Series |

|

|

Wireline Series |

AWL,BWL,NWL,HWL,PWL,NWL-2,NWL-3 |

|

T2 Series |

T2 46,T2 56,T2 66,T2 76,T2 86,T2 101 |

|

T6 Series |

T6 76,T6 86,T6 101,T6 116,T6 131,T6 146, T6S 101,T6S 116 |

|

T Series |

T36,T46,T56,T66,T76,T86 |

|

Z Series |

Z46,Z56,Z66,Z76,Z86,Z101,Z116,Z131,Z146 |

|

B Series |

B36,B46,B56,B66,B76,B86,B101,B116,B131,B146 |

|

WF Series |

HWF,PWF,SWF,UWF,ZWF |

|

WT Series |

RWT,EWT,AWT,BWT,NWT,HWT |

|

WM Series |

EWM,AWM,BWM,NWM |

|

WG Series |

EWG,AWG,BWG,NWG,HWG |

|

Others |

NMLC,HMLC,LTK48,LTK60,BGM,NGM,ADBG,TBW,TNW, |

Suggestions:

SOFT ROCK FORMATIONS

• Low RPM’s

• Large diamonds/cutters

• Large waterways for better flushing and higher GPM flow rates

• Hard matrix for longer bit life

HARD ROCK FORMATIONS

• High RPM’s

• Small waterways

• Soft matrix to expose more cutting elements

Related Products